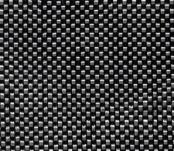

Carbon fiber can be found everywhere from auto racing to aerospace. Its unmatched strength for light weight, high strength, aerodynamic parts, have made it a widespread favorite in today's composite industry.

Rayplex offers a wide selection of carbon fiber reinforcements. We go a long way to ensure that all of the products we handle are First Quality, manufactured to the highest standards for maximized strength and perfect cosmetics.

For crystal clear laminating use the Rayplex #282 epoxy. This brings out the beauty of the carbon fibre weave.

**FIND IT HERE: Rayplex #282 Clear Epoxy Resin

Features are:

- High stiffness

- High tensile strength

- Low weight

- High chemical resistance

- High temperature tolerance

- Low thermal expansion

Carbon Fibre Tubes

Carbon Fibre TubesBig or small, we are bound to have round carbon fiber tubing that suits your needs.

CARBON FIBER REPAIR KIT.

Carbon fiber fabric, also known as carbon fiber cloth or carbon fiber textile, is a material made from carbon fibers that are woven together to form a flexible and strong fabric. Carbon fibers are composed of carbon atoms bonded together in a crystalline structure. These fibers have excellent mechanical properties, including high tensile strength, low weight, and resistance to corrosion, making them ideal for a wide range of applications.

Here are some key features and uses of carbon fiber fabric:

- High Strength-to-Weight Ratio: Carbon fiber fabric is known for its exceptional strength-to-weight ratio. It is significantly lighter than many traditional materials while being incredibly strong. This property makes it popular in aerospace, automotive, and sporting goods industries.

- Low Thermal Expansion: Carbon fibers have a low coefficient of thermal expansion, which means they don't expand or contract significantly with changes in temperature. This property is useful in applications where dimensional stability is crucial.

- Corrosion Resistance: Carbon fibers are highly resistant to corrosion, making them suitable for use in harsh environments or corrosive chemical settings.

- Electrical Conductivity: While carbon itself is not a good conductor of electricity, carbon fiber fabrics can be engineered to have specific electrical conductivity properties. This makes them valuable in applications where both strength and electrical conductivity are needed, such as in aircraft and automotive components.

- Aerospace and Aviation: Carbon fiber fabric is widely used in the aerospace and aviation industries for manufacturing aircraft components, including fuselages, wings, and structural elements. Its lightweight nature helps reduce the overall weight of the aircraft, improving fuel efficiency and performance.

- Automotive: In the automotive industry, carbon fiber fabrics are used to make components like body panels, interior trim, and structural parts. These components help reduce the weight of vehicles, enhancing fuel efficiency and handling.

- Sports and Recreation: Carbon fiber fabric is popular in sports and recreational equipment, such as bicycles, tennis rackets, golf clubs, and fishing rods. The lightweight and strong nature of carbon fiber enhance performance in these products.

- Marine and Boating: Carbon fiber fabrics are used in the construction of boats and other marine vessels due to their resistance to corrosion and lightweight properties.

Carbon fiber fabrics come in various weaves and patterns, including plain weave, twill weave, and satin weave, each with its specific characteristics and properties. The choice of weave depends on the intended application and the desired balance between strength, weight, and aesthetics.